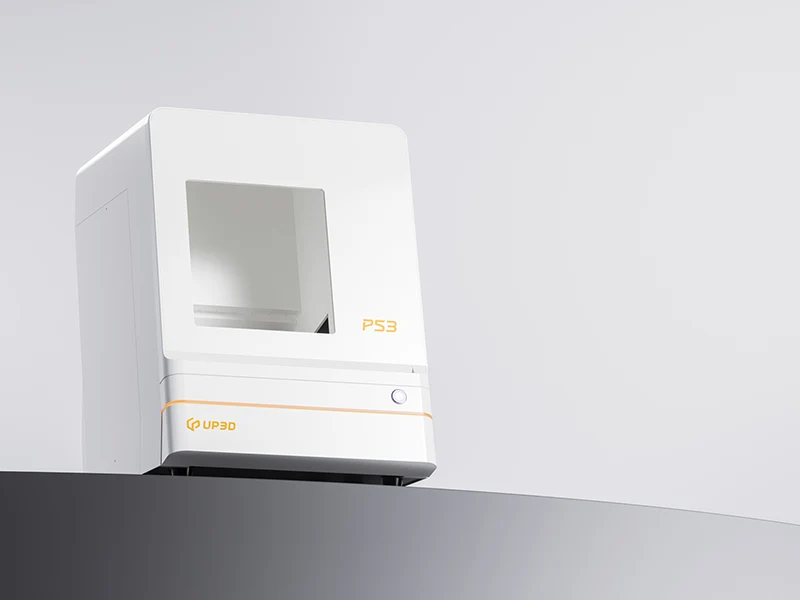

P53- Easier Smarter and More Effective Ways to Fit in with Your Lab

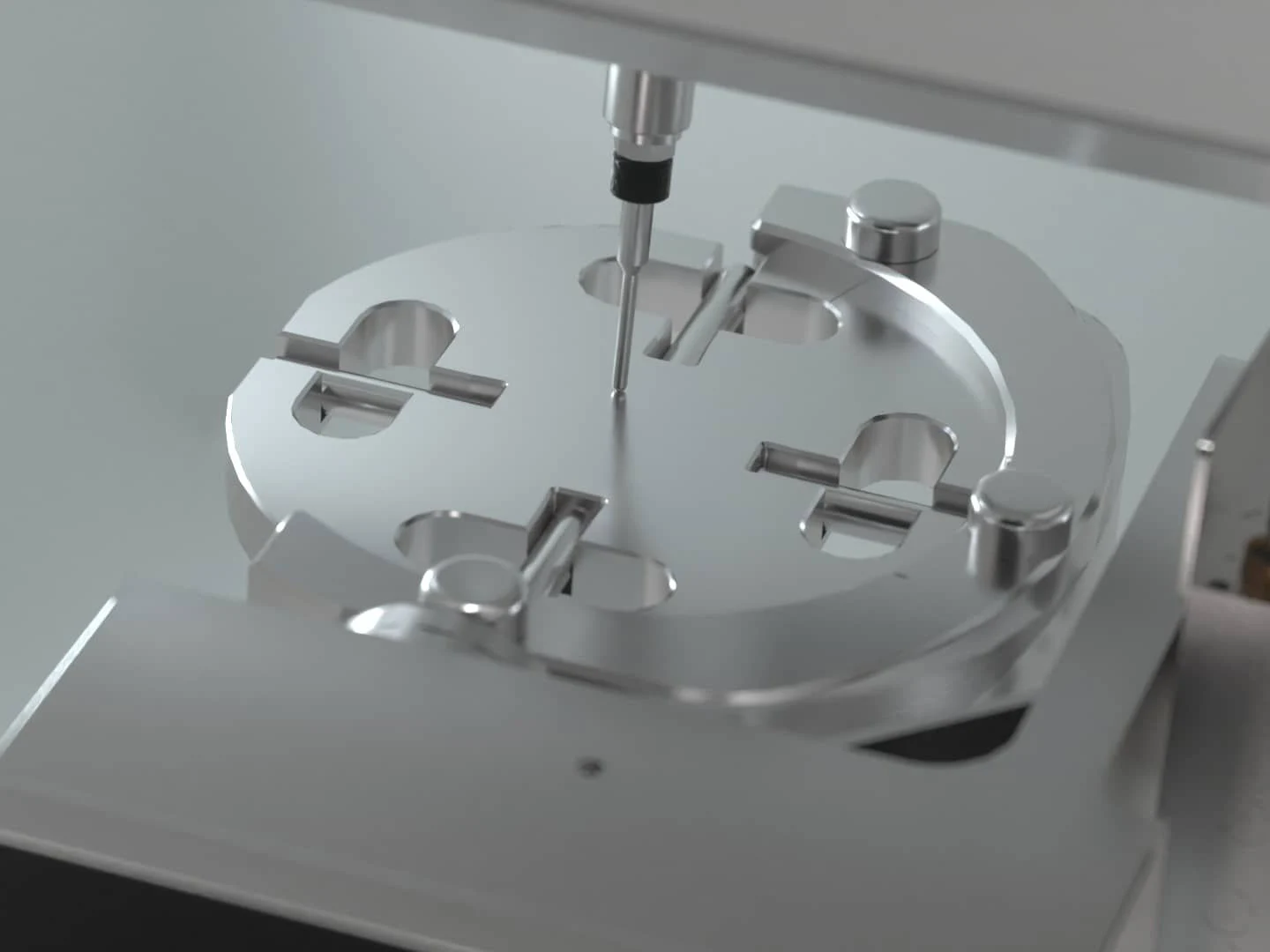

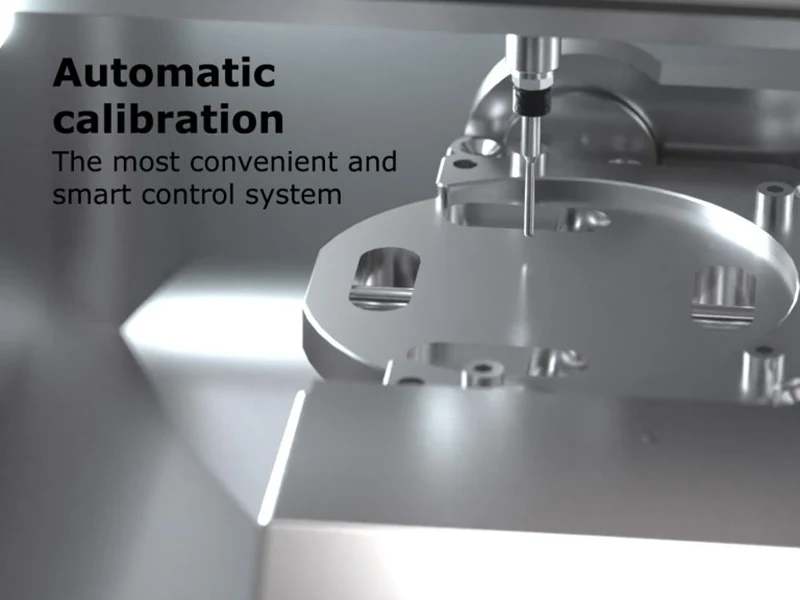

Automation

- Automatic Calibration

- Automatic tool changer

- Automatic Calculation of tools lifetime

LED Milling Progress. Display the milling progress of P53 can reduce personnel inspection time & improve efficiency

Maximizing Your Efficiency- P53- 5-axis milling machine

A 5-axis milling machine developed by UP3D, has intelligent features such as automatic calibration, monitoring of burs life, and automatic renewal, the P53 digitizes & scales up traditional processing methods.

90° Milling

It is convenient for the embrasure processing of the anterior teeth, making the finished teeth closer to the designed teeth, and the shape is more nature and complete.

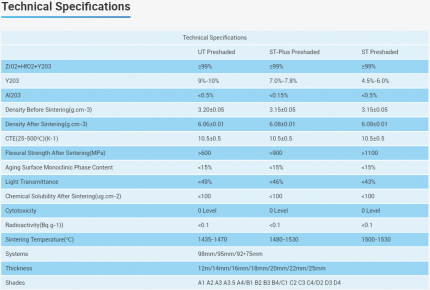

Product Parameters

UP3D 5-Axis Milling Machine

Model- P53

Dimension- 718*443*628 (mm)

Weight- 87kg

Input Voltage- AC 200~240V 50~60Hz

Maximum Power- 1.1KW

Spindle Power- 0.35KW at max

Axis Quantity- 5-Axis simultaneous motion

Milling Range- X/Y/Z:167/206/104mm A:±30° B:±360°

Milling Mode- Dry milling

Max Rotation Speed- 30,000 rpm

Max Feed Rate- 3000 mm/min

Tools Quantity- 11

Tools Changing Method- Automatic>

Spindle Cooling- Air cooling with compression air (Air pressure 0.25~0.35MPa)

Milling Materials- Zirconia, Wax, PMMA, PEEK and soft materials

Milling Time- Coping: Zirconia-10min Wax- 4.5min | Crown: Zirconia-13min

Wax-5.5min

Tools Diameter- 2 + 1 + 0.6 (Φ4 calibration bur) Disc Specification- Round disc with Φ98, 30mm max for thickness

Spindle Clamping Diameter- Φ4.0mm

Cam Supported- UPCAM and Millbox

Data Transmission- Network interface