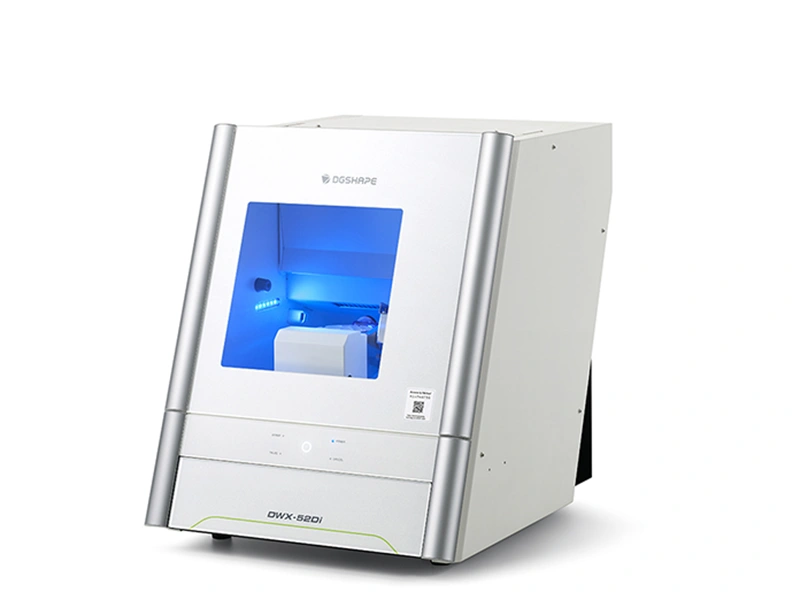

The new Roland DWX-52Di is a dental milling machine designed to make CAD/CAM dental restorations simple and accurate. Accuracy and accuracy are the main criteria that the developers relied on when creating the machine.

- Distinctive features

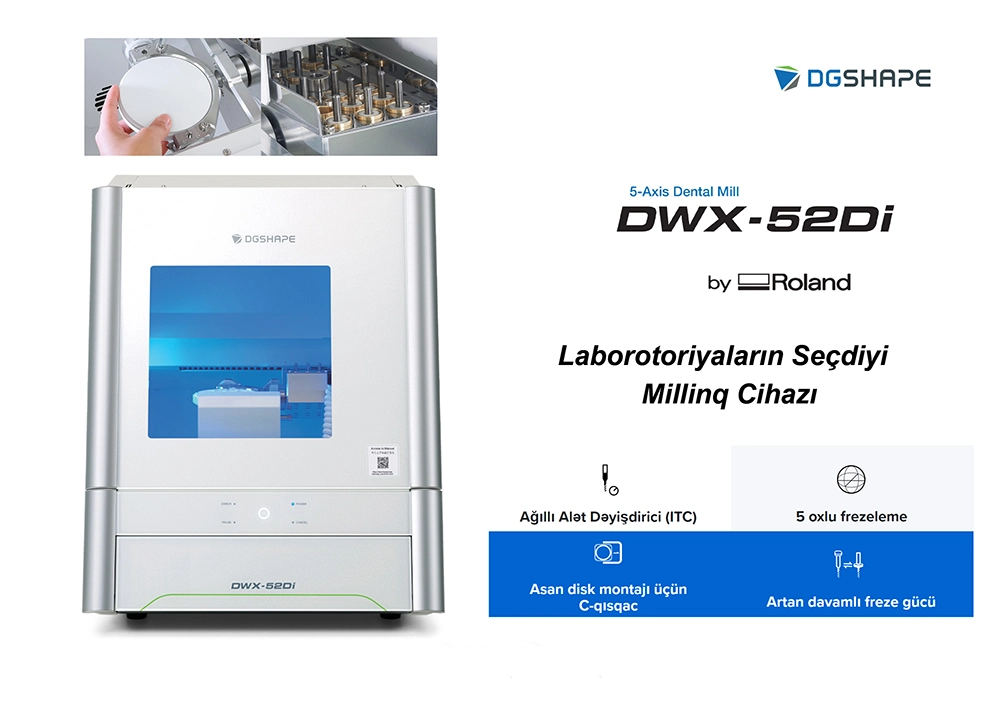

- 5-axis precision machining, tilt angle increased to 30 degrees

- Processed material: zirconium oxide, wax, PMMA, composite resins, PEEK

- Workpieces in the form of blocks and disks are automatically moved along the X, Y and Z axes, with simultaneous rotation 360 degrees clockwise or counterclockwise. In the new DWX-52Di machine for complex operations, the critical angle of inclination of the material along the B axis has been increased to 30 degrees. Ball screw drives (ball screw drives) are used in most CNC milling systems because… they have reduced friction, which increases service life. All moving parts are reliably protected from dust.

- New C-clamp for easy disc installation and adjustment The new DWX-52Di disc holder has a crescent shape, in which the disc is secured with bolts, which is much more convenient and eliminates the possibility of turning the disc.

- The Automatic Tool Changing (ATC) system with tool length sensor allows individual orders and entire discs to be processed without operator intervention using different tools. In order not to evaluate the quality of work already on the finished product, rely on the diagnostic function. It will warn you in advance about tool failure, saving your time and materials.

Powerful built-in vacuum ionizer to reduce dust The built-in powerful vacuum antistatic ionizer prevents chips from PMMA discs from sticking to the internal walls of the machine.

Maximum convenience and ease of useMany new functions ensure continuous milling and make it even more convenient.

The robust construction ensures the machine’s stability, and its elegant design makes it a great addition to any laboratory. A convenient modern tool compartment performs its functions perfectly.

LED indicators for current process status signal

Virtual panel (VPanel) allows you to configure from your computer, send CAM files to the DWX-52Di for milling and monitor the milling processEasy access to the workspace for cleaning and changing tools.

- .

- .

- .

- .

.

- .

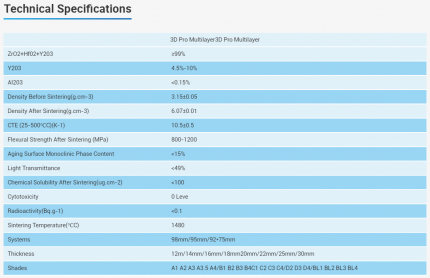

Specifications

- Processed materials: Zirconium oxide (sintered), modeling wax, PMMA, TRINIA, PEEK, plaster

- Shape of the loaded workpiece: Section with levels: diameter 98.5 mm, height 10 mm; Main section: diameter 95 mm, max. height 60 mm Pin Type: Diameter: 6mm Operating speed: XYZ axis: 6–1800 mm/min

- Spindle motor: Brushless DC motor

- Spindle speed: 6,000–30,000 rpm

- Rotation axis movement angle: A: ±360°, B: ±30°

- Number of installed tools: 10

- Connected tool: Shank diameter: 4 mm, length: 40–55 mm

- Allowable compressed air pressure: 0.02–0.2 MPa

- Interface: USB

- Control command set: RML-1, NC programming language

- Power: Voltage and frequency: AC 100 to 240 V ± 10%, 50/60 Hz, 2.0 A (overvoltage category II, IEC 60664-1)

- Noise level: During operation: up to 70 dB(A) (without milling); Standby: up to 45 dB(A)

- LxWxH: 660x495x600 mm

- Weight: 67 kg

- .

- .